Market Challenges

Market Challenges

Extreme Cleanliness is the necessity while manufacturing Semiconductors, hard disks etc., since even a few particles at Micro levels and chemical contaminants at Nano levels may cause a major failure and subsequent losses to the manufacturer by affecting their production yield and product let-downs. Cleanliness of the design of cleanrooms are quantified by standards such as ISO and others. To achieve them according to the design requirements as per the regulations & standards, the particulate and chemical filters must be properly selected, installed & maintained throughout the usage of controlled ambient of those cleanrooms. The impact to environment and its resultant damages in case of some emergencies, due to the products used in the design of cleanrooms are governed by standards such as FM, UL & others.

Solution

Clean rooms are essential :

A cleanroom is a controlled environment designed to filter out microscopic pollutants such as dust, dirt, airborne particles, and other microbes. These specialized rooms provide the highest levels of cleanliness and hygiene. Here’s why we need them:

Quality Assurance : Cleanrooms play a crucial role in industries where product quality is paramount. By significantly reducing the concentration of volatile particles in suspension, cleanrooms ensure that sensitive materials remain uncontaminated during production.

Hygiene and Safety : Cleanrooms prevent the escape of hazardous biomaterials handled inside. For instance, virology or nuclear research laboratories use cleanrooms as a protective shield to safeguard exterior facilities and staff.

Ecosystem Within Production: Essentially, a cleanroom functions as its own ecosystem within a wider production line. Working within this micro-climate allows for the creation of highly sensitive products with minimal environmental disruption and adherence to the highest specifications.

EQUIPMENT

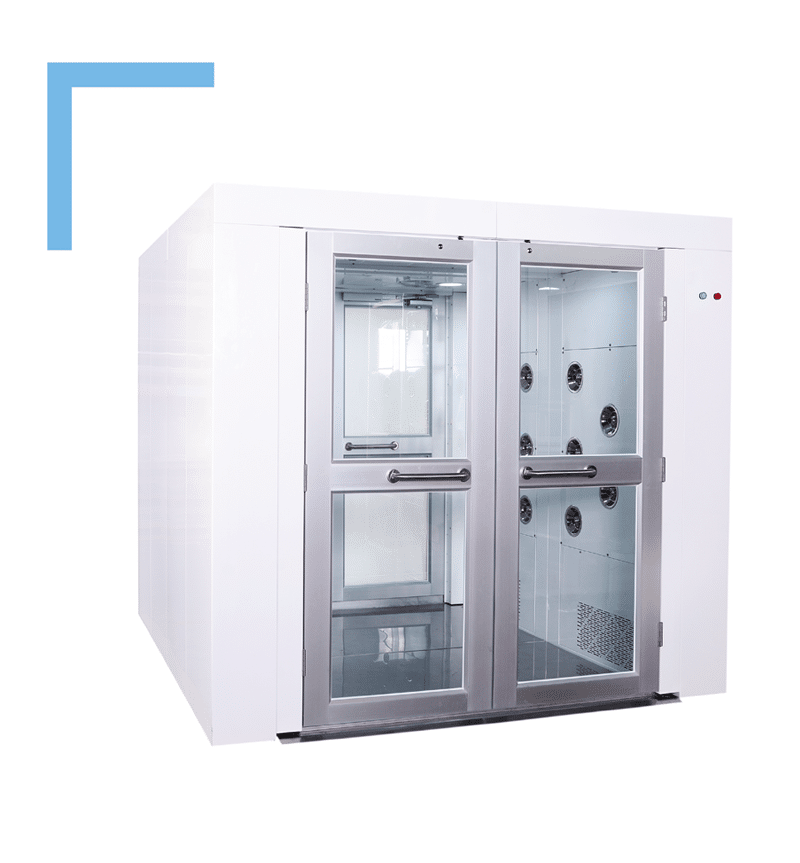

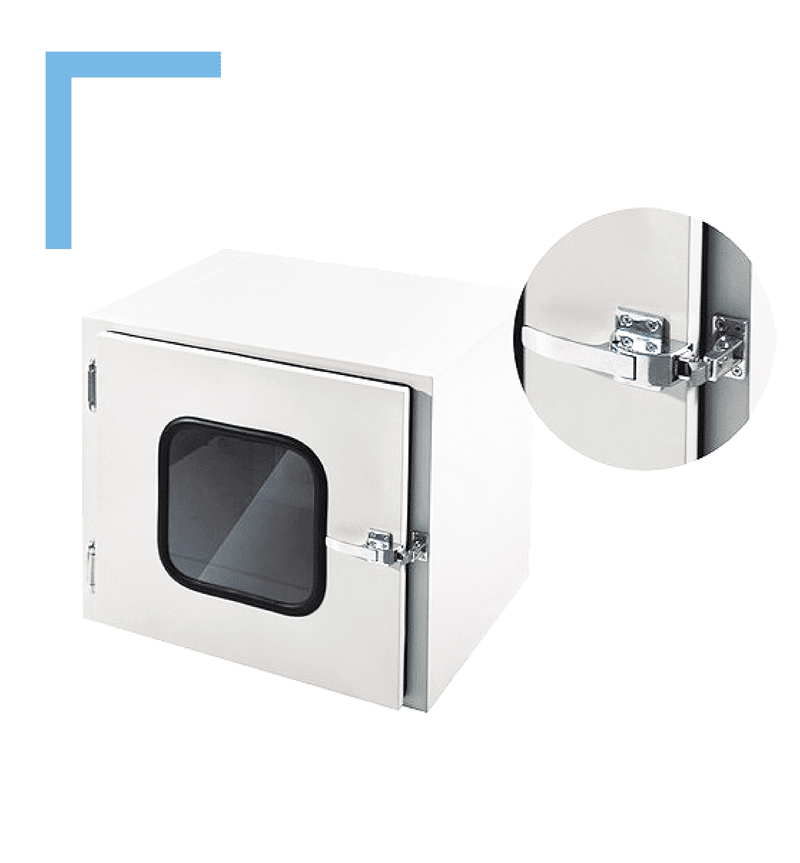

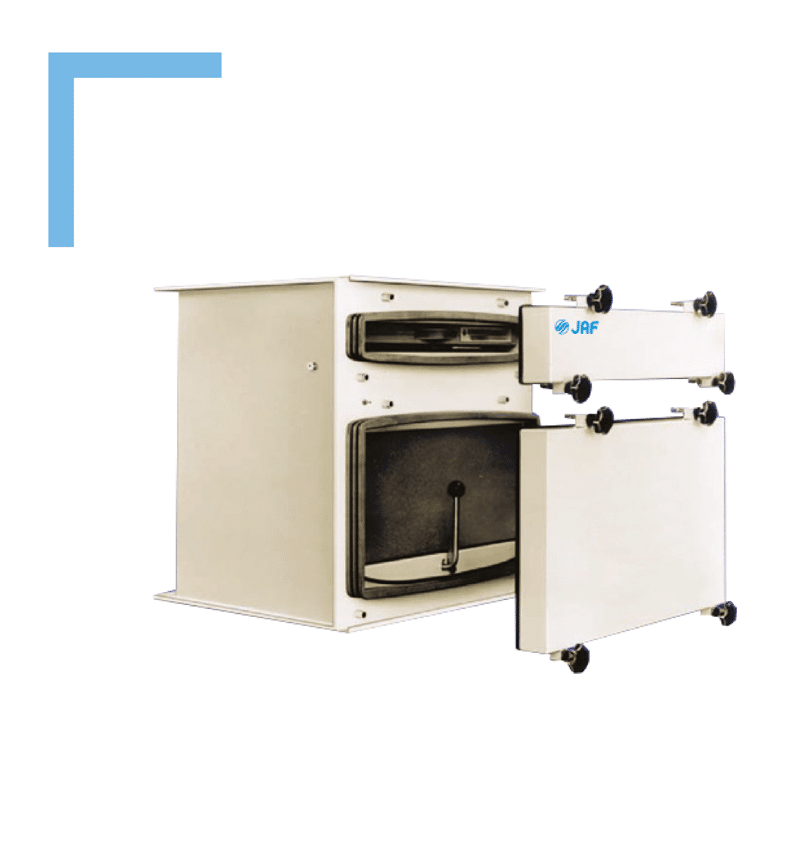

- Self-contained chambers

- Minimizes particulate matter entering or exiting the clean space

- High velocity HEPA-filtered air jets

- CE marking compliance

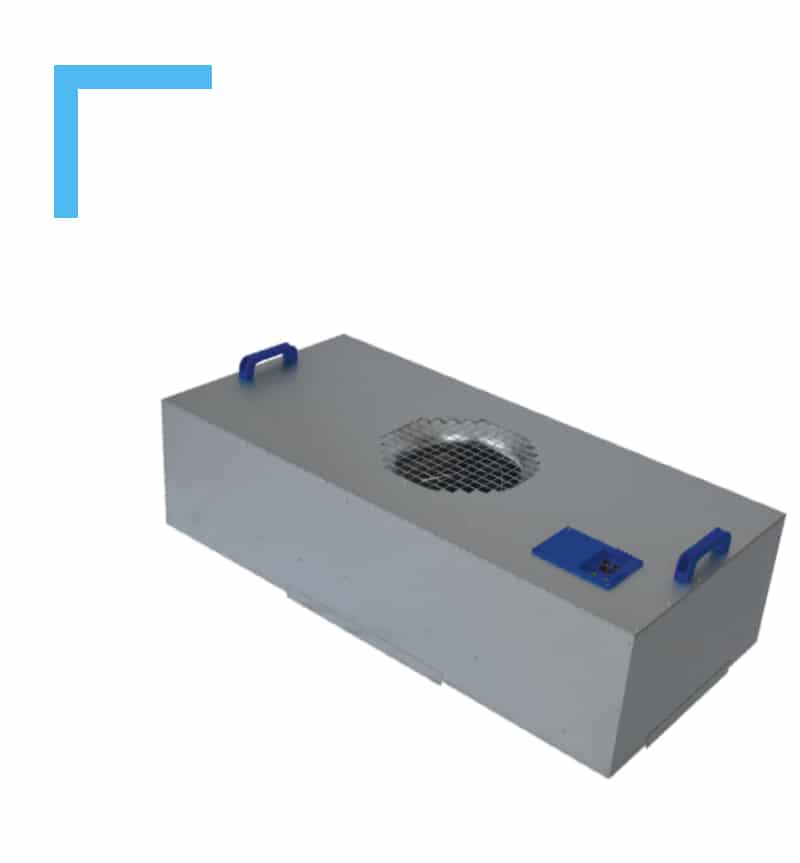

- Standalone adjustable filtered clean air supply.

- Laminar air flow

- Ease of assemble and disassembly

- JAF Pass Box Air Shower is equipped with air jetting system which provides high velocity blower fan and HEPA filtration systems for the safe transfer of materials between classified areas or between a classified area and a non-classified area.

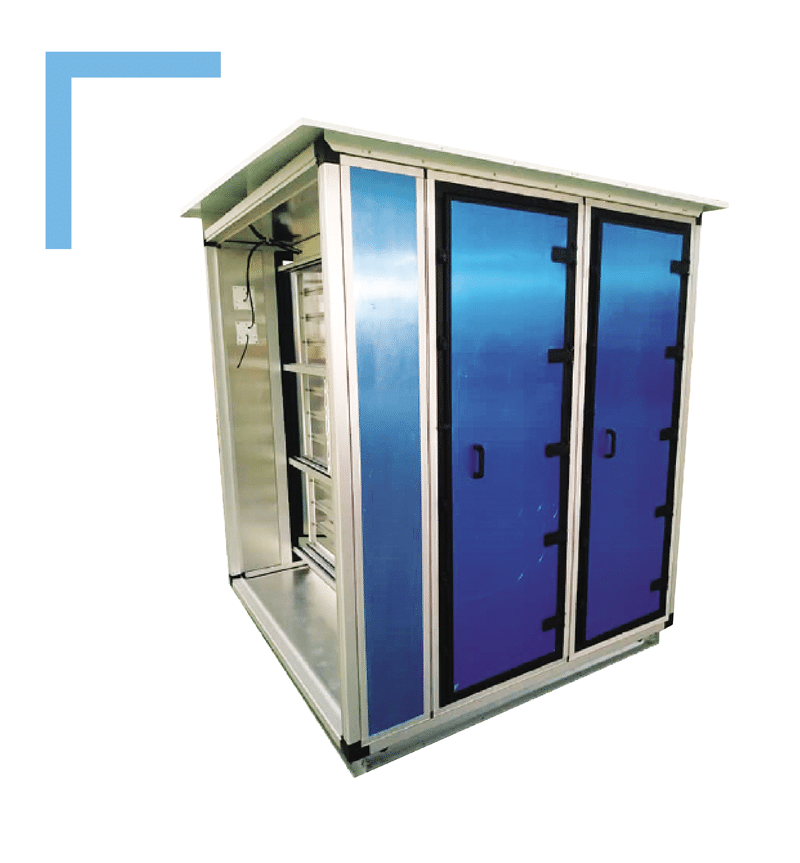

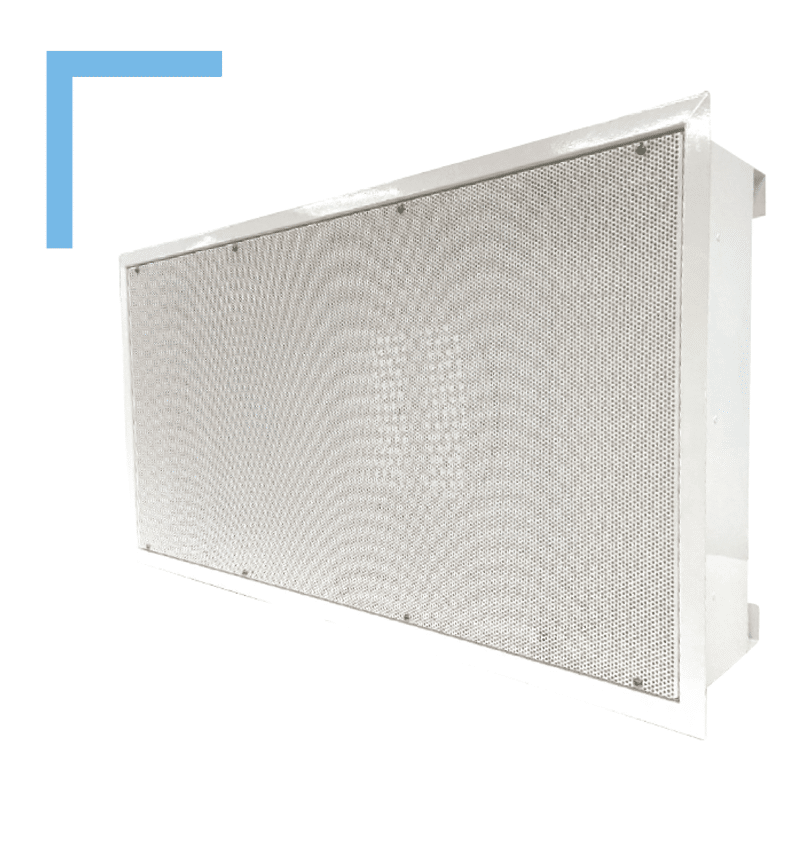

- Single & double wall constructions.

- Space saving Side Access design.

- Customized design available to suit both commercial & industrial requirements.

- Available in various sheet metal options (Aluminium, Galvanized steel, Stainless steel, painted steel)

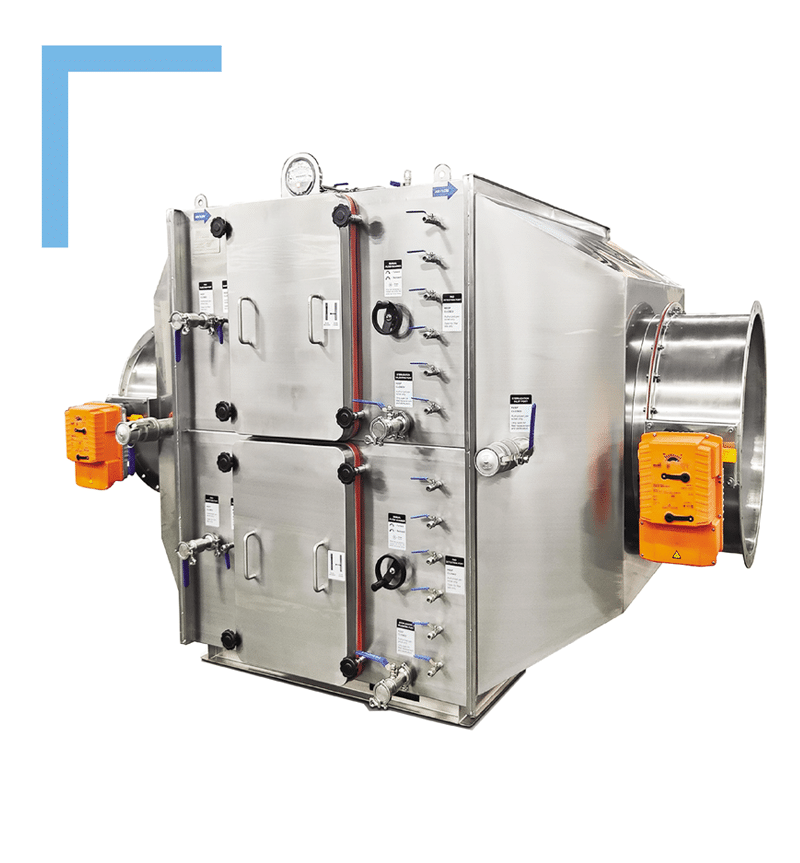

- More than 50 standard size housings utilizing standard filter size components.

- Options available to include in-built Fan housing, base frame U-channels, lifting lugs, weather proofing, Intake louvers & rain louvers

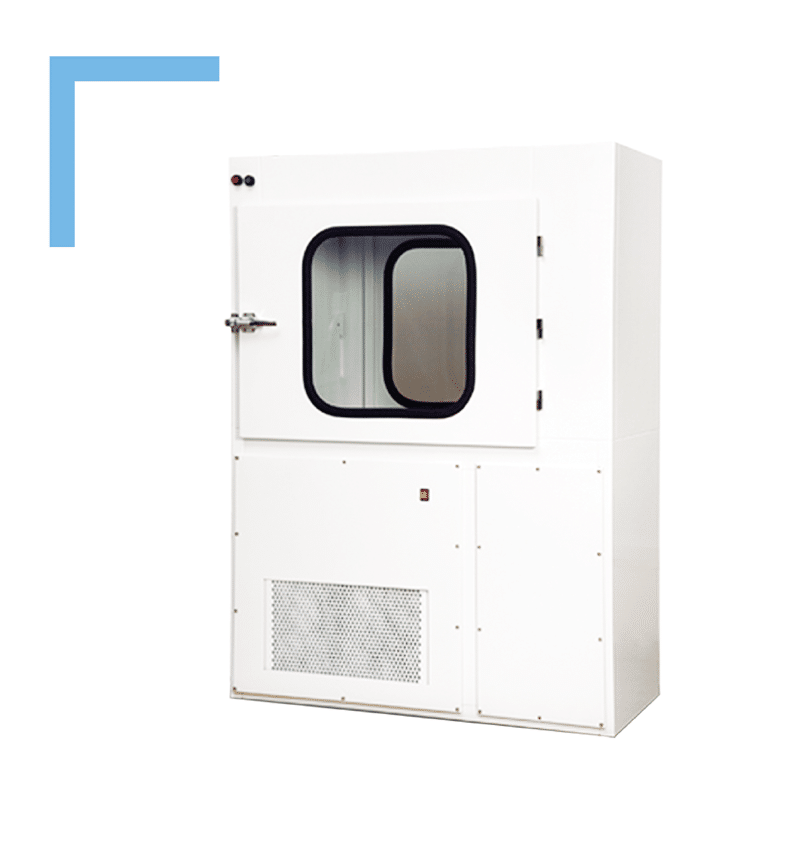

- Specially designed for the safe transfer of materials between classified areas or between a classified and non classified area.

- Standard, reliable design

- Safety assurance & total resistant proof from contaminations

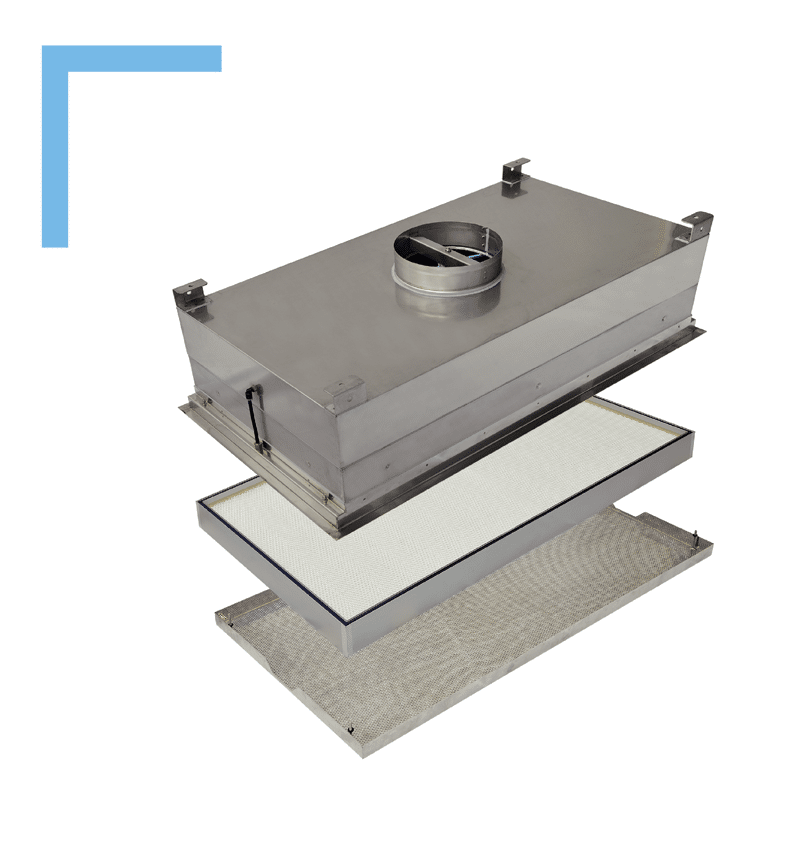

- H13

- 2’ X 2’, 2’ X 4’

- G.I., Aluminium, Stainless steel, Powder baked

- Suitable with LunaKleen or LunaCel HEPA filter

- Room side changeable HEPA filter

- Available in single phase (1p) and three phase (3p)

- With variable speed controller

- Smart Electronic

- Control (EC) FFU system

- Standard module 2’x2’, 2’x4’ and 4’x4’

- Room side replaceable mini pleat design filter

- Wide range of efficiencies from H10 to U16

- Low off-gasing, final filter for pharma and microelectronics, cleanroom & equipment

- 100% filter leak test for guaranteed performance

- Room side adjustable diffuser (upon request)

- Stainless steel, Aluminium & Galvanised steelwith epoxy powder coating.

- 1 housing with 2 system appllications, allow both gel & gasket seal filter.

- Two test ports available, PAO injection port & sampling port.

- Quick-connect air-tight to PAO injectoin and sampling port.

- Perfect airtight structure filter device to eliminate contamination due to leakage or radioactive dust gas.

- Compatible with combination of pre-filter, carbon filter & HEPA filter according to the usage purposes.

- clean and sterile operating environment of electronics, biotechnology, medicine, food, precision instruments and other industries

- easy to use, high flexibility, easy installation, short construction period and portability

- It can be used singly or connected in multiples to form a strip-shaped clean area

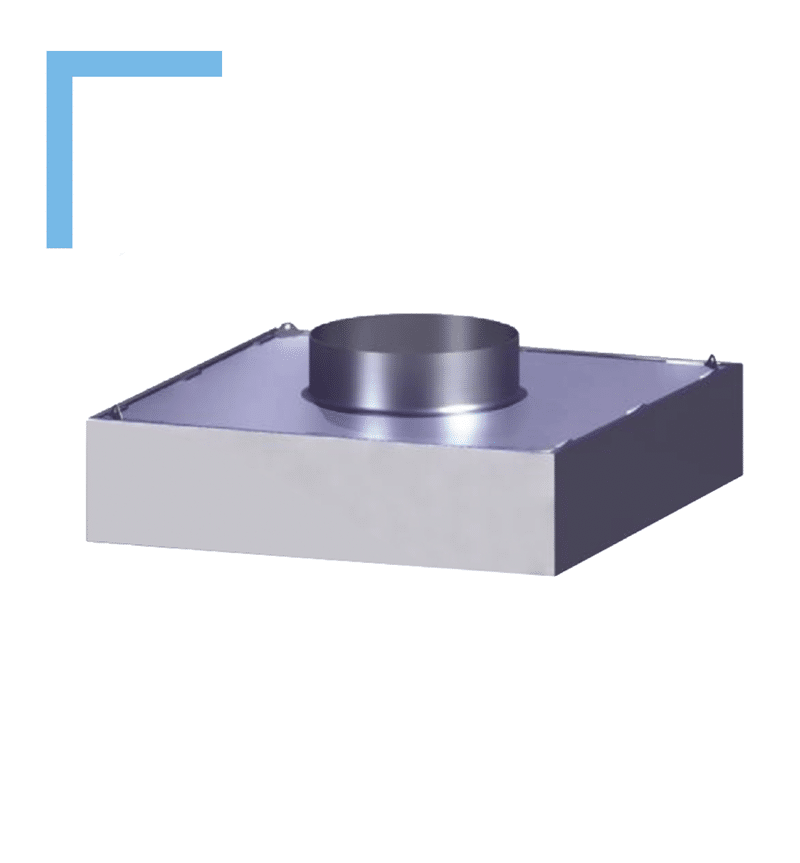

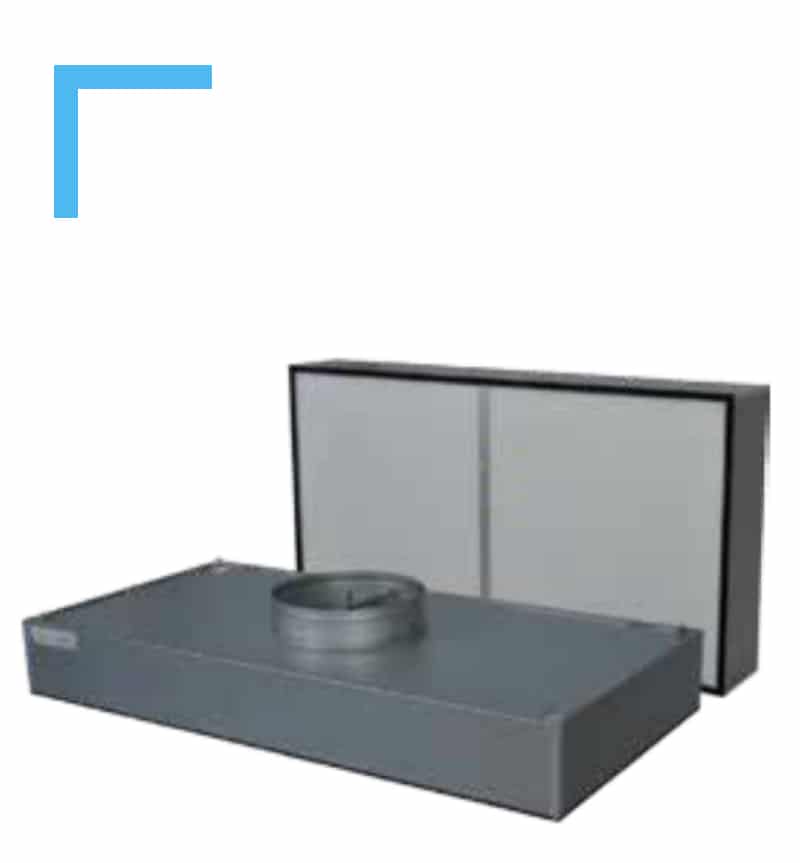

- Compact HEPA & ULPA grade filters with hood cover

- Mini-pleat design

- Wide range of efficiency from H10 to U16

- Low off-gassing filter material to meet the cleanroom requirement

- 100% HEPA filter scan test for guaranteed performance

- Room side adjustable diffuser

- Disposable unit for optimum filter performance with an individual ducted system

- Optional for test port

- UL 900 certified

ULPA/HEPA

- Premium grade HEPA air filtration media (option with Virus Guard Media

- Tested filter media performance against bacteria and virus)

- Low pressure drop

- UL 900 certified

- Premium grade HEPA air filtration media (option with Virus Guard Media)

- UL 900 certified

- Premium grade HEPA air filtration media (option with Virus Guard Media)

- High temperature filter up to 250oC

- UL 900 certified

- Premium grade HEPA air filtration media (option with Virus Guard Media)

- Low pressure drop

- Energy saving and environmental friendly

- High efficiency for final filtration in air conditioning systems filter housings and diffusers

- UL 900 certified

- Premium grade HEPA air filtration media (option with Virus Guard Media)

- Moisture resistant fibreglass

- Slim, light and compact type HEPA and ULPA filters

- Mini-pleat design

- Wide range of efficiency H10 to U16

- Low off-gassing filter material to meet the cleanroom requirement

- 100% HEPA filter scan test for guaranteed performance

- Optional for gel seal

- UL 900 Certified

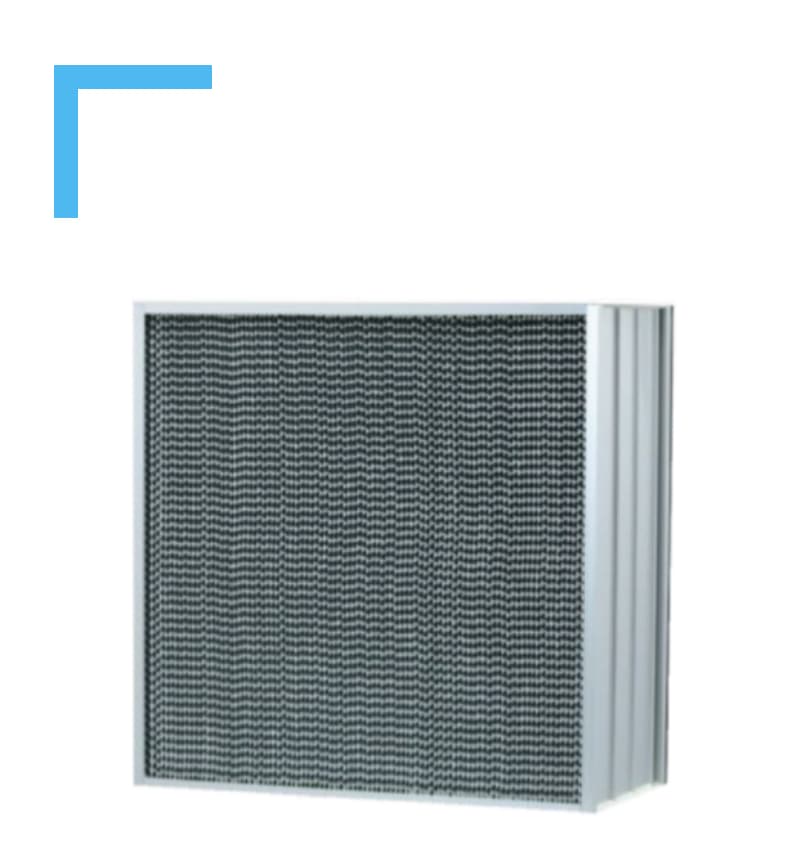

- Designed for high air volume application

- More media areas with low pressure drop

- Longer lifespan

- Low energy consumption

- Available from H10 to H14

- Design for high air volume applications

- The enlarged media area ensures lower averages

- pressure drop and longer lifespan filter

- Low energy consumption

- Available for H10 – H14

- Moisture resistant, fire retardant fibreglass

- Design for high air volume applications

- The enlarged media area ensures lower average pressure drop and longer lifespan filter

- Low energy consumption

- Available for H10 – H14

- Premium grade HEPA air filtration media

- Lower pressure drop than fibreglass

- Low off gassing

- High durability media

- High acid resistant to corrosive environment

- Ultra-high efficiency PTFE membrane

- Ultra-low resistance to achieve optimum energy efficiency

- Negligible off-gassing properties (eg. boron, sodium, potassium, silicon)

- High durability media, minimize transportation cost, rough

handling and installation damages - High acid resistance to corrosive environment (acids, alkali, organic substances)

- Lower pressure drop than fibreglass

- UL 900 Certified

- Compact HEPA & ULPA grade filters with hood cover

- Mini-pleat design

- Wide range of efficiency from H10 to U16

- Low off-gassing filter material to meet the cleanroom requirement

- 100% HEPA filter scan test for guaranteed performance

- Room side adjustable diffuser

- Disposable unit for optimum filter performance with an individual ducted system

- Optional for test port

- UL 900 certified